Product Description:

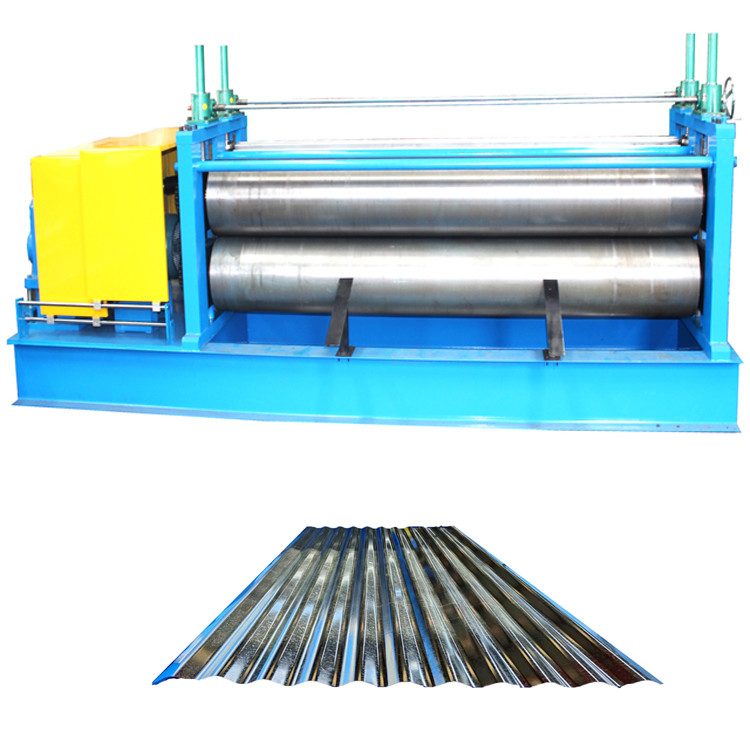

The Roof Tile Roll Forming Machine is equipped with a high-speed forming system that can produce up to 10-15m/min, making it one of the most efficient machines in the market. Its high-speed forming system ensures that the roofing sheets produced are of high quality, consistent, and accurate.

The machine is also designed with a compact size of 5.8*1.6*1.5m, making it easy to install and operate in any factory or workshop. Its size also ensures that it does not take up too much space, leaving enough room for other machines and equipment.

The Roof Tile Roll Forming Machine comes with a 70mm shaft diameter, which is strong and durable, ensuring that the machine operates smoothly and efficiently. Its shaft diameter ensures that the machine can withstand heavy usage and produce high-quality roofing sheets for a long time.

This machine is designed to produce roofing sheets of different widths, including 1000mm and 1250mm. This feature makes it a versatile machine that can produce roofing sheets of different sizes to meet the needs of its customers.

The Roof Tile Roll Forming Machine is a must-have machine for any factory or workshop that specializes in the production of roofing sheets. Its versatility, high-speed forming system, and durability make it one of the best machines for producing high-quality roofing sheets.

Features:

- Product Name: Roof Tile Roll Forming Machine

- Cutting Tolerance: ±2mm

- Size: 5.8*1.6*1.5m

- Control System: PLC Control System

- Roller Material: 45# Steel, Hard Chrome Coated

- Thickness: 0.13-0.3mm

This metal roof machine is also known as an ibr roof sheet making machine, and is a cold roll forming machine.

Technical Parameters:

| Technical Parameters |

Specifications |

| Product Name |

Roof Tile Roll Forming Machine |

| Material |

Aluminum, Galvanized Steel, Color Steel, Etc. |

| Thickness |

0.13-0.3mm |

| Shaft Diameter |

70mm |

| Control System |

PLC Control System |

| Width |

1000mm,1250mm |

| Cutting Tolerance |

±2mm |

| Cutting Mode |

Hydraulic Cutting |

| Weight |

4T |

| Forming Speed |

10-15m/min |

| Size |

5.8*1.6*1.5m |

Applications:

Our roof tile roll forming machine is designed to work efficiently, with a forming speed of 10-15m/min. This means that it is capable of quickly producing large quantities of roofing tiles, making it ideal for use in commercial roofing projects. The machine is also designed to be easy to use and maintain, making it perfect for both experienced and novice roofers.

The FMS roof tile roll forming machine is perfect for use in a variety of different application occasions and scenarios, including:

- Residential roofing projects

- Commercial roofing projects

- Industrial roofing projects

- Renovation projects

- Construction projects

With its CE certification and high-quality construction, the FMS roof tile roll forming machine is a reliable and durable machine that is sure to meet all of your roofing needs. The minimum order quantity for this product is 1 set, and the price is negotiable. The packaging details include naked with plastic film, and the delivery time is approximately 40 days. Payment terms include T/T and L/C, and the supply ability is 20 sets per month. The voltage required for operation is 380V/50Hz/3Phase, and the thickness of the materials that can be used is between 0.3-0.8mm. The cutting mode is hydraulic cutting, making for a precise and clean cut every time.

Support and Services:

The Roof Tile Roll Forming Machine product comes with technical support and services to ensure optimal performance and longevity. Our team of experts is available to assist with any questions or issues that may arise during installation, operation, and maintenance of the machine.

We offer comprehensive training to operators and maintenance personnel to ensure that they are equipped with the knowledge and skills necessary to operate and maintain the machine safely and efficiently.

In addition, we provide regular maintenance and repair services to keep the machine in top condition and prevent downtime. Our team can also provide upgrades and modifications to the machine to keep it up-to-date with the latest technology and industry standards.

Our goal is to provide our customers with the support and services they need to get the most out of their investment in the Roof Tile Roll Forming Machine.

Packing and Shipping:

Product Packaging:

- The Roof Tile Roll Forming Machine will be securely packaged in a wooden crate.

- The machine will be wrapped in a layer of protective film to prevent scratches and damage during transportation.

- The wooden crate will be reinforced with metal strapping to ensure that the machine remains in place and does not shift during transit.

Shipping:

- The Roof Tile Roll Forming Machine will be shipped via sea or air, depending on the customer's preference and location.

- Shipping costs will be calculated based on the destination and mode of transportation.

- Delivery times will vary depending on the shipping method chosen and the destination of the machine.

- Customers will be provided with tracking information so that they can monitor the progress of their shipment.

|

Product Name

|

|

automatic C/Z pulin roll forming machine

|

|

C pulin roll forming machine

|

|

carriage plate machine

|

|

roof and wall panel color steel roll forming machine

|

|

840-1000-1200-1250mm single board machine

|

|

Self-lock roof panel roll forming machine

|

|

double layer roll forming machine

|

|

glazed tile roll forming machine

|

|

floor deck roll forming machine

|

|

water chaneel roll forming machine

|

|

door bottom girder machine

|

|

seismic stabilizer bracket

|

|

Rolling shutter machine

|

|

highway guardrail roll forming machine

|

|

cable tray roll forming machine

|

|

C-type steel high-speed keel machine

|

|

C-grid light keel roll forming machine

|

|

plate shearing machine

|

|

slitting machine

|

|

hydraulic curving machine

|

|

ridge cap roll forming machine

|

|

colorful stone coated metal roof tile machine

|

|

Embossing mahine

|

|

plate shearing machine

|

|

bending machine

|

|

Hydraulic uncoiler

|

|

Color steel sandwich panel roll forming machine

|

We have the most professional technical team and rich experience in production and manufacturing. We are the manufacturer, and the customer requirements as the driving force for our development, keep pace with The Times and keep innovating.if you are interested

our machine and want to know more information ,please contact me at first time .

We can customize and design according to your needs,+8-6-177-369-86-169 please contact me

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!