Product Description:

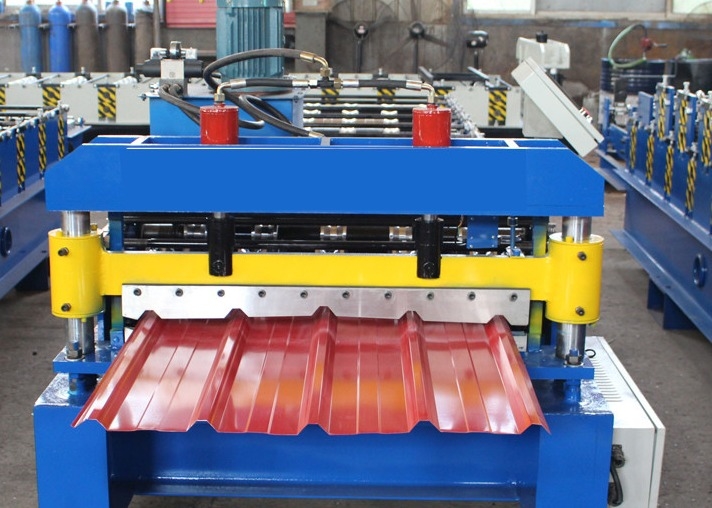

The Roof Tile Roll Forming Machine is designed to work with a voltage of 380V/50Hz/3Phase, which is the standard voltage in most countries. The machine is also equipped with a powerful 4KW motor that ensures that it operates efficiently and effectively.

The Roof Tile Roll Forming Machine is a cold roll forming machine that is designed to produce high-quality roofing tiles. The machine is easy to operate and requires minimal maintenance, making it an ideal choice for small and medium-sized businesses.

The machine weighs 2T, which makes it easy to move around the production facility. The compact design of the machine also ensures that it takes up minimal space, making it an ideal choice for businesses with limited space.

In summary, the Roof Tile Roll Forming Machine is a high-quality tile roofing sheet making machine that is designed to produce high-quality roofing tiles. The machine is equipped with a 70mm shaft diameter, chain drive drive mode, a voltage of 380V/50Hz/3Phase, a 4KW motor, and weighs 2T. It is also a cold roll forming machine that is easy to operate and requires minimal maintenance. The compact design of the machine ensures that it takes up minimal space, making it an ideal choice for businesses with limited space.

Features:

- Product Name: Roof Tile Roll Forming Machine

- Voltage: 380V/50Hz/3Phase

- Cutting Tolerance: ±2mm

- Shaft Diameter: 70mm

- Control System: PLC Control System

- Size: 5.8*1.6*1.5m

- Product Type: Cold Roll Forming Machine

Technical Parameters:

| Technical Parameter |

Value |

| Product Name |

Roof Tile Roll Forming Machine |

| Cutting Tolerance |

±2mm |

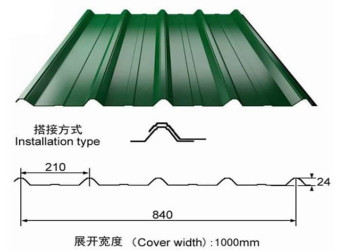

| Thickness |

0.3-0.8mm |

| Voltage |

380V/50Hz/3Phase |

| Size |

5.8*1.6*1.5m |

| Cutting Mode |

Hydraulic Cutting |

| Forming Speed |

8-15m/min |

| Material |

Aluminum, Galvanized Steel, Color Steel, Etc. |

| Roller Material |

45# Steel, Hard Chrome Coated |

| Roller Stations |

11 Stations |

| Shaft Diameter |

70mm |

Applications:

The Roof Tile Roll Forming Machine is an ideal product for various roofing applications. With its high-quality metal sheets, it is suitable for commercial, industrial, and residential buildings. The machine is perfect for creating metal roofs that require durability and longevity. The roof metal sheet machine is also suitable for creating roofs with different designs, shapes, and sizes, making it a versatile product.

The Roof Tile Roll Forming Machine is perfect for creating metal roofs for different occasions and scenarios. It is ideal for creating roofs for warehouses, factories, and other industrial buildings. The machine can also be used for creating roofs for commercial buildings such as shopping malls, retail stores, and office buildings. Additionally, the machine is perfect for creating roofs for residential buildings such as apartments, houses, and villas.

The Roof Tile Roll Forming Machine is also suitable for creating metal roofs for different weather conditions. It is perfect for creating roofs for areas with heavy rainfall, snow, and strong winds. The machine's durability, strength, and longevity make it an ideal product for different weather conditions.

In conclusion, the Roof Tile Roll Forming Machine is a high-quality product that is perfect for creating metal roofs for various occasions and scenarios. Its durability, strength, and versatility make it an ideal product for different weather conditions. The machine's certification with CE ensures its quality and reliability, making it a product worth investing in for your roofing needs.

Customization:

roof tile roll forming machine is manufactured in

China and comes with a

CE certification . The minimum order quantity is

1 set and the price is

negotiable . Our packaging details include naked with plastic film and the delivery time takes

40 days . We accept payment terms of

T/T and L/C and have a supply ability of

20 sets/month .

The roof tile roll forming machine has a shaft diameter of 70mm and can handle thicknesses of 0.3-0.8mm . The forming speed is 8-15m/min and the machine size is 5.8*1.6*1.5m . The roller material is made of 45# steel with hard chrome coating.

Support and Services:

Our Roof Tile Roll Forming Machine is designed to provide efficient and reliable production of high-quality roof tiles. We offer technical support and services to ensure that our customers have a smooth and trouble-free experience with our product.

Our technical support team is available to answer any questions and provide guidance on installation, operation, and maintenance of the machine. We also offer training programs for operators to ensure that they have the knowledge and skills needed to operate the machine efficiently and safely.

In addition, we provide services such as machine inspection, repair, and replacement of parts to ensure that the machine is always in optimal condition. Our goal is to provide our customers with the best possible experience and help them achieve their production goals with our Roof Tile Roll Forming Machine.

Packing and Shipping:

Product Packaging:

The Roof Tile Roll Forming Machine is packaged securely in a wooden crate to protect it from damage during shipping. The machine is carefully placed and secured within the crate to prevent any movement or shifting during transportation.

Shipping:

The Roof Tile Roll Forming Machine is shipped via sea freight in a 20-foot container. The container is loaded with the wooden crate holding the machine and is sealed to ensure its safety during transportation. The estimated shipping time is 30-35 days.

FAQ:

Q1: What is the brand name of this product?

A1: The brand name of this product is FMS.

Q2: What is the model number of this product?

A2: The model number of this product is roof tile roll forming machine.

Q3: Where is this product made?

A3: This product is made in China.

Q4: Does this product come with any certification?

A4: Yes, this product comes with a CE certification.

Q5: What is the minimum order quantity for this product?

A5: The minimum order quantity for this product is 1 set.

Q6: Is the price of this product negotiable?

A6: Yes, the price of this product is negotiable.

Q7: How is this product packaged?

A7: This product is packaged naked with plastic film.

Q8: What is the delivery time for this product?

A8: The delivery time for this product is 40 days.

Q9: What are the payment terms for this product?

A9: The payment terms for this product are T/T and L/C.

Q10: What is the supply ability of this product?

A10: The supply ability of this product is 20 sets per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!