Stone Coat Metal Roofing Tile Stone Coat Products Roof Tile Roll Forming Machine Production Line

We are manufacturer of design and produce the color stone coat metal roofing tile production line. Also produce the various of the stone coat metal roofing tiles.

Colorful stone coat metal roofing tile is a new advanced roof material which adopt the high and new technology, use the non-corrosibility galvalume steel as the basic plate, use the acrylic resin which has the good weather resistance as the adhesives, use the colorful natural sandy gravel as the surface. Because of its nice appearance, lightweight, durable and environmental, vriety of styles, it is becoming the major product in the international roof materials in recent years.

And it is also used in the high-grade building in domestic, owing to diffuse reflection of the vermiculites, its flamboyant color and tridimensional appearance, stone-coated metal roof tile is enjoying a great popularity all over the world.

Our designed production line includes 5 major Full automatic working sections. And also includes other machines, just like one punch-63T, one plate shearing machine, one automatic shearing and slitting machine, one bending machine, one hydraulic pressing machine, one ridge cap mold, one manual decoiler, and so on.

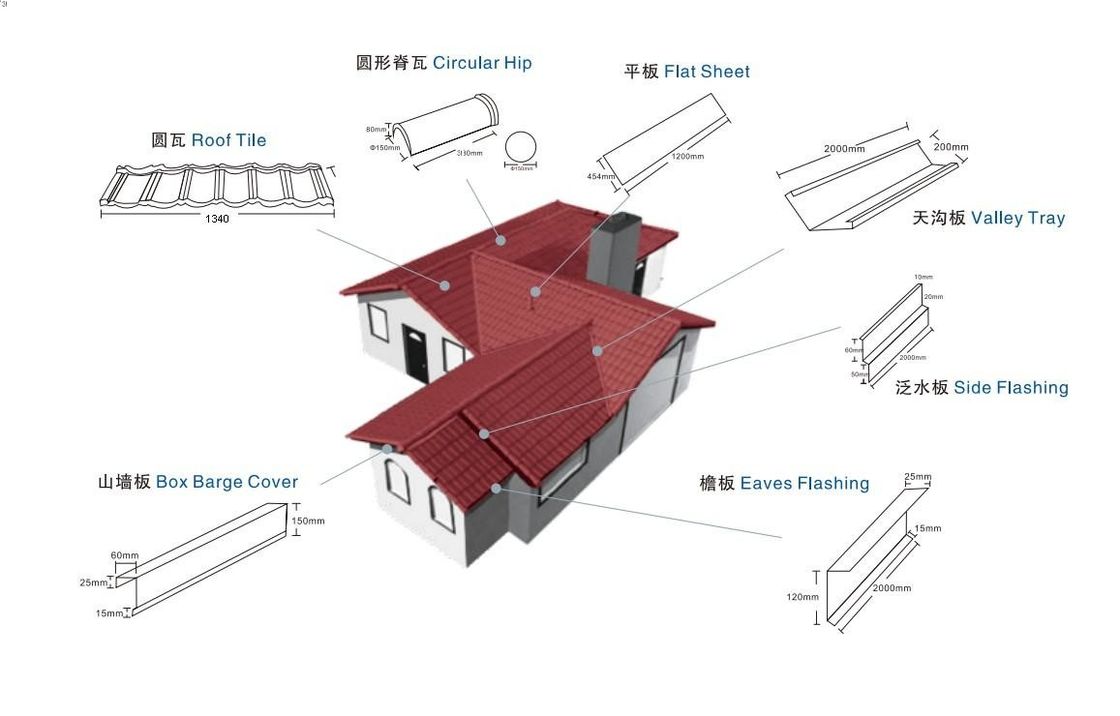

So if you have this stone coat metal roofing tile production line, you can produce a whole sets of beautiful roof tiles, as shown below.

Main Technical Specifications

Main section:

1 Auto bottom glue spraying section

2 Auto color jump stone coated section

3 The first time drying section

4 Auto face glue spraying section

5 The second time drying section

Detailed parameters are as follows

1 Auto bottom glue spraying section ( Sports spray gun )

| No. |

Item |

Description |

| 1 |

Dimensions

|

3000 mm*2260 mm*1800 mm(L*W*H)

|

| 2 |

Framework

|

Steel welding

|

| 3 |

Transmission

|

Cycloidal pinwheel reducer power 1.5kw frequency conversion speed control

|

| 4 |

Conveying

|

12A precision roller chain reciprocating

|

| 5 |

Auto spray gun

|

2 pcs ZPQ-1 high-pressure automatic spray gun(auto working and shut off )

|

2 Auto color jump stone coated section, Auto overall feeding and recycling of the colorful stone

| No. |

Item |

Description |

| 1 |

Dimensions

|

4000 mm*2260 mm*3000 mm(L*W*H)

|

| 2 |

Framework

|

Steel welding

|

| 3 |

Transmission

|

Cycloidal pinwheel reducer power 1.5kw frequency conversion speed control

|

| 4 |

The stone bucket

|

2sets auto Cylinder opening ( Fully auto operation and shutdown of the stone coated)

|

| 5 |

Sand hoist

|

1set 3kw Used for automatic sand loading ,recovering and recycling

|

3 The first time drying section ( For the first drying after the tile coated stone is finished)

| No. |

Item |

Description |

| 1 |

Dimensions

|

3000 mm*1610 mm*1500 mm(L*W*H)

|

| 2 |

Transmission

|

Cycloidal pinwheel reducer power 3 kw

|

| 3 |

Speed control

|

Inverter speed regulation

|

| 4 |

Structure type

|

Frame type insulation wall 1.2 Cold plate bending forming Insulation cotton filling

|

| 5 |

Framework

|

Steel welding

|

| 6 |

Conveying

|

Single side bent plate chain with support

|

4 Auto face glue spraying section

After the first time drying is completed, the sprayed surface adhesive is used to fix the gravel on the surface. A protective film is formed on the surface to make the sandy surface durable and beautiful, and the surface has a shiny feel.

| No. |

Item |

Description |

| 1 |

Dimensions

|

3000 mm*850 mm*2200 mm(L*W*H)

|

| 2 |

Framework

|

Steel welding

|

| 3 |

Transmission

|

RV reducer frequency conversion speed regulation power 1.5kw

|

| 4 |

Spraying method

|

ZPQ-1 high-pressure automatic spray gun 2 pcs

|

| 5 |

Spray transmission

|

step motor 12N.M

|

| 6 |

Control method

|

Proximity switch control (discover tile glue gun automatically opens and closes automatically after spraying)

|

| 7 |

Dust removal device

|

one set of adsorption dust removal power 1.5kw

|

5 The second time drying section

| No. |

Item |

Description |

| 1 |

Dimensions

|

3000 mm*1610 mm*1500 mm(L*W*H)

|

| 2 |

Transmission

|

Cycloidal pinwheel reducer power 3 kw

|

| 3 |

Speed control

|

Inverter speed regulatio

|

| 4 |

Structure type

|

Frame type insulation wall 1.2 Cold plate bending forming Insulation cotton filling

|

| 5 |

Framework

|

Steel welding

|

| 6 |

Conveying

|

Single side bent plate chain with support

|

6 These equipments is sprayed with primer, and the cloth flip board is controlled by plc.

Advantages

1 It saves a lot of glue consumption. This equipment uses an encoder to accurately detect the walking position of the tile. After finding the tile, the spray gun automatically turns on and closes after spraying is completed. Not spraying glue, saving the consumption of glue.

2 The capacity of the drying tunnel is increased to save energy and increase the speed. The common baking method is to enter the tile in the long direction, and we now use a horizontal entry into the drying tunnel and tilt it into the drying tunnel. Entering the drying tunnel can hold 5 pieces in the long direction, and can accommodate two pieces. At the same speed, our tiles stay longer in the drying tunnel and dry more thoroughly.

3. The inductive sand bucket sees the tiles open and closes when finished, which greatly reduces the burden on the hoist and extends the life of the hoist compared to the previous uninterrupted quicksand.

4. The automatic turning plate reduces the manual labor and reduces the labor intensity. The manual turning plate and the sand are easy to damage the plate. The current automatic turning plate improves the product quality.

Guarantee

1. Guaranteed against malfunctions due to manufacturing defects for1 years after date of purchase except Electrical parts.

2. Repairs will not be performed even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

Payment terms

40% in advance as down payment

60% is paid before the shipment is processed

Delivery

FOB: Tianjin Xingang Port

The Delivery Time: 60 working days after the down payment is received.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!