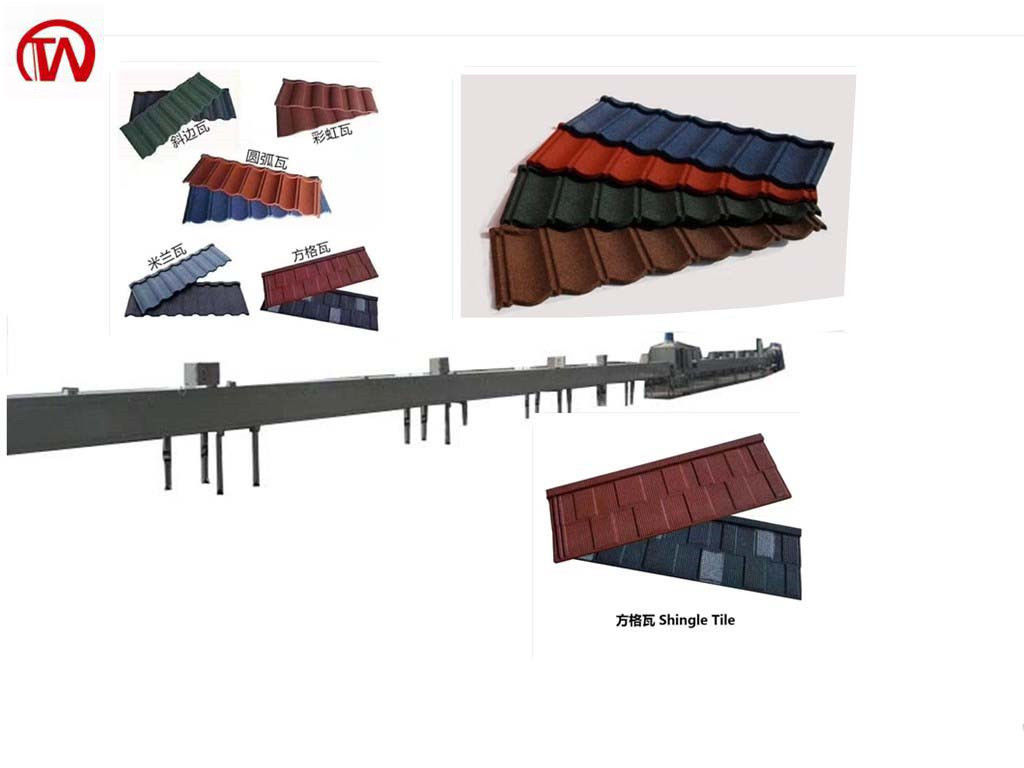

New Type Stone Coated Roof Tile Roll Forming Machine L Shape 0.4mm

This machine including 4 parts:

a,Auto bottom glue spraying section,

b.auto stone coated section

c.auto face glue spraying section

d.drying section.

1. Auto bottom glue spraying section:

Dimensions:3.8 m*1.5 m*1.5 m(L*W*H)

Frame structure: welded steel φ50×φ100 rectangular square tube welding

Transmission: 12A chain, repeated transmission, the rubberized section is a five-corner belt transmission

Spraying device: 1PQ-1 high pressure airless spraying machine, 1 set of voltage regulator

Motor power: 1.1KW 1 set, variable frequency speed control

2. Auto stone coated section

Dimensions:6.5 m*1 m*1.9 m(L*W*H)

Frame structure: welded steel φ50×φ100 rectangular square tube welding

Transmission: 12A chain, repeated transmission

Bottom conveyor belt: 1 for bottom sand recovery, power 1.5KW

Blowing fan: 1 set, power 4KW, 10 air nozzles

Hoist: 1 set, power 2.2KW for sand recovery and upgrade to sand bucket for sand recycling

3. Auto face glue spraying section

Dimensions:2.9 m*1 m*1.7 m(L*W*H)

Frame structure: welded steel φ50×φ100 rectangular square tube welding

Transmission mode: pentagon belt transmission, motor power 1.1KW

Spraying method: fixed spraying, fixed spray gun, automatic spraying of tiles

Spray pump: pneumatic diaphragm pump, spray gun 2PQ-1 type

Cleaning sink: 1 for cleaning the pentagonal belt

4. Drying section

Dimensions:65 m*1.61 m*1.35 m(L*W*H)

Frame structure: welded steel φ50×φ100 rectangular square tube welding

Chain drive: 16A chain

Heating tube: 90 infrared heating tubes, power 90KW

Transmission motor: cycloidal pinwheel reducer 5.5KW

5. Drying section overall arrangement

The stone coated metal roofing production line are installed in ‘ L ’ shape, many advantages, such as space saving, small floor space, compact equipment connection, easy operation and good stability.

I. Guarantee

a. Guaranteed against malfunctions due to manufacturing defects for 1.0year after date of purchase.Spare parts will be made free of charge,but freight cost should be paid by buyer.

b. Repairs will not be performed even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!