| Weight |

About 2500kg |

| Size |

About 8m x 1.2m x 1.3m (length x width x height) |

| Thickness |

1.0-2.0mm |

| Power |

11kw |

| Production Capacity |

10-20m/min |

| Voltage |

380V/50HZ 3 Phase(as Customer's Request) |

| Forming rollers material |

45# steel with CNC machining and surface is being hard chrome |

| Cutter material |

CR12 mould steel, with quenched treatment |

| Controlling system |

DELTA PLC and Converter |

| Hydraulic unit motor power |

Main motor power: 5.5kw |

| 5.kw |

Working Flow and Main parts of Steel Channel Making C Stud Roll Forming Machine

Uncoiling —— Material Feeding —— Roll Forming —— Step Making —— Automatic Cutting —— Products Receiving

Stud and track roll forming machine configuration components

|

|

|

|

|

Double head hydraulic uncoiler

|

|

|

|

|

|

|

Adjustable feeding platform

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Delta PLC electronic control system

|

|

|

Supporter/Automatic Stacker

|

|

|

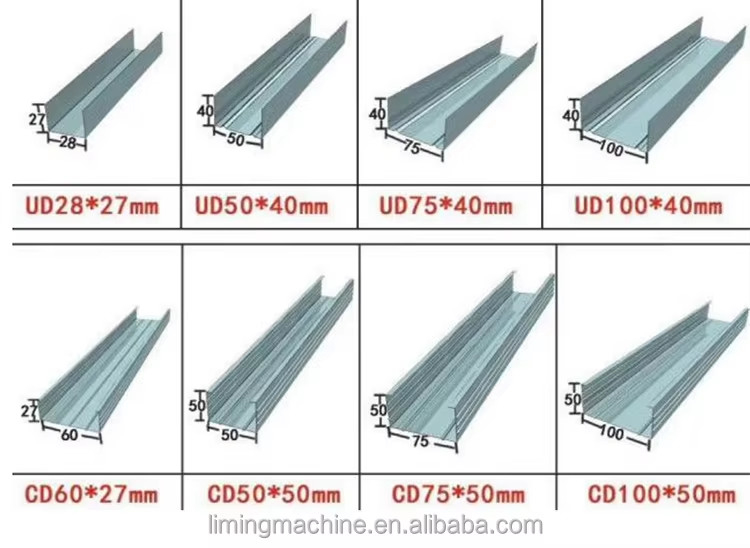

Choice of standard EU size or custom size

|

3 Tons Passive Decoiler

Coil inner Diameter: ¢460-520mm

Max out diameter of the coil: ¢800mm

Max Coil Width: 500mm

|

|

Roll Forming Part

Thickness of sheet: 0.4-1.2mm

Motor Power: 7.5 kw forming system

Roller material: C45 steel

Base Frame: 350 H steel welded

Roller Stations About 14-18 stations forming

Roller Material 45# Steel with quenching

Shaft Material 45# Steel Diameter 60mm shaft

|

|

|

Hydraulic Cutting---Stop Cutting

Cutting after forming: Cut the sheet after roll forming to required length

Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will

automatically start.

Material of blade: CR12mov with heat treatment

Length measuring: Automatic length measuring

Tolerance of length: 10m+/- 2mm

|

|

Control Box

* Power supplier: 220V, 60 Hz, 3Phase (adjusted with therequestment)

* length & quantity measurement automatically;

* length & quantity controlled by PLC

* Length inaccuracy can be amended easily.

* Control panel: Button-type switch and touch screen

* Unit of length: millimeter (switched on the control panel)

|

|

|

Output Table

It adopts welded steel and supported roller to

transmit the products.

Size:2 meters length 2 units

|

CD and UD 2 in 1 roll forming machine | 2 in 1 u stud machine | 2 in 1 c stud machine | C profile roll forming machine | U stud roll forming machine

To save space and price, some customer like to choose 2 in 1 roll forming machine, it means one machine can produce 2 shapes products. We can customize machine as your need, like

1. Omega profile and u channel 2 in 1 roll forming machine

2. Omega profile and angle bead 2 in 1 roll forming machine

3. Omega profile and C channel 2 in 1 roll forming machine

4. CD and UD 2 in 1 roll forming machine

5. C channel and angel bead 2 in 1 roll forming machine

6. Angle bead and u stud 2 in 1 roll forming machine

Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type:

Angle bead roll forming machine | Corner bead production line | Metal angle bead machine | Corner bead roll forming machine | V shape roll forming machine | Steel wall angle bar roll forming machine

Angle bead roll forming machine popular sell in many countries, size common include 20*20 mm, 25*25 mm, 27*27 mm, 30*30 mm. Product thickness common between 0.3-0.6 mm, machine details is like up type:

Product Profile

Omega profile roll forming machine | Omega channel roll forming machine | Omega channel roll forming machine | Top hat roll forming machine

Omega profile roll forming machine popular sell in many countries. Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

3 in 1 c channel machine | multiple c channel machine | C u channel roll forming machine

Multiple C channel machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details

U channel roll forming machine | gypsum u channel making machine | U stud roll forming machine

U channel roll forming machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc,

Steel Channel Making C Stud Roll Forming MachineAdvantage:

1. Famous Brand, quality is guaranteed.

2. Full Automatic Computer Control make easy to operation.

3. Machine roller and shaft is produced by exact demands and control . The roller material processing method is by CR12 MOV heat treatment 58℃-62℃ . The product quality is durable and long service life .

Packaging Details

1. Select containers of different specifications for transportation based on the actual volume and weight of the packaged goods.

2. Wipe the entire equipment with rust proof oil and use a thin film for dust protection. 3. PLC controller and electric cabinet

are covered with foam film, and vulnerable parts are protected by wooden cases. 4. Spare parts and some small parts are packed in

a plastic toolbox

.

FQA

1.Are you manufacture or factory ?

we are manufacture and we have more than 15 years'experience .

2.what's your free warranty of machines? and how to make sure quality of machines ?

our warranty of machine is 18 months and after we finish machines ,we will supply video of testing machines ,and welcome to visit our factory and inspect machines on site.

3.Engineer avilable oeverseas?

our engineer can go aborad for installation of machines and train your workers ,and we have local engineers in kenya ,zimbabwe etc .

4.if spares broken ,how to deal with it?

we can send new spare by DHL courier ,you can receive them within 5 to 7 days.

5.what's your payment term ?

our payment term is 30% of deposit by T/T,another balance payment after we finish machine before shipment .

6.how to visit your factoty ?

you can fly to Beijing airport first ,and by airport bus or taxi to Beijing train station ,we will help you book train ticket from

beijing to our city in advance ,then we pick you up from our train station.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!