Product Description:

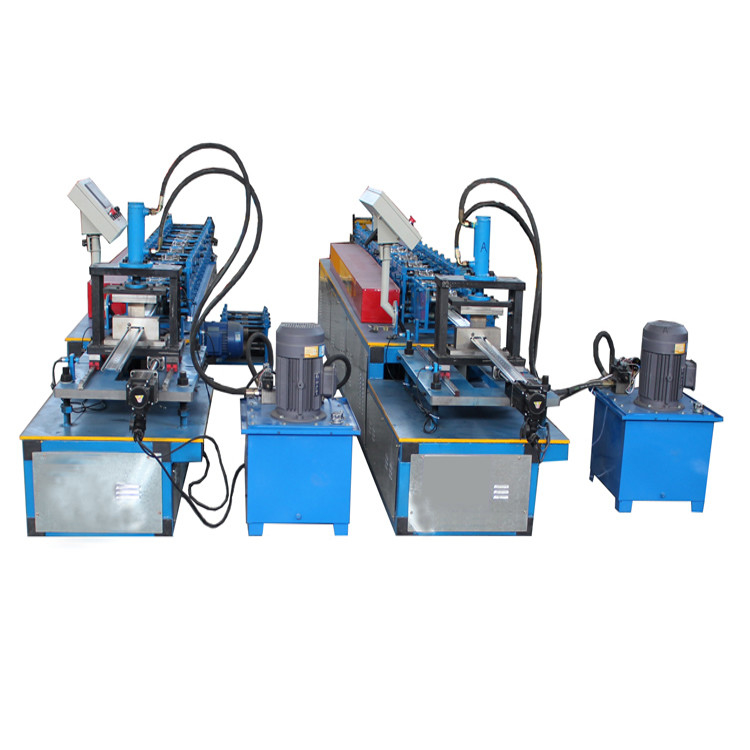

The Shutter Door Roll Forming Machine is a state-of-the-art piece of equipment designed for the production of high-quality shutter doors. This machine stands out in the market for its robust construction, precision engineering, and high efficiency. With the ability to form metal sheets into the desired shutter door profiles, this roll forming machine is a valuable asset for businesses in the construction and manufacturing sectors.

Our Shutter Door Roll Forming Machine boasts an impressive 18 roller stations, which are the backbone of this machine's performance. Each station is meticulously designed to ensure uniformity and accuracy in the shaping process. The roller stations work in harmony to progressively form the metal sheet into the final profile with minimal stress and deformation, preserving the material's strength and integrity.

At the heart of this machine is the Product Name: Shutter Door Roll Forming Machine, a name that has become synonymous with reliability and quality in the industry. This machine's reputation is well-earned, thanks to its consistent output and ability to handle various metal thicknesses, specifically ranging from 0.8 to 1.2mm. This versatility allows manufacturers to produce a wide range of shutter doors to meet different customer requirements and industry standards.

The Forming Speed of this rolling shutter machine is adjustable, ranging from 0 to 15 meters per minute. This feature enables operators to set the speed according to the specific requirements of the task at hand, optimizing production time and ensuring that each shutter door is formed with precision and care. Faster production speeds do not compromise the quality of the end product, making it possible to achieve high output without sacrificing the high standards expected of shutter doors.

One of the key attributes of the Shutter Door Roll Forming Machine is its advanced Control System. Equipped with a PLC (Programmable Logic Controller), the machine offers seamless operation and easy programmability. The PLC system ensures that every aspect of the roll forming process is controlled with precision, from the motion of the roller stations to the cutting of the formed sheets. This level of control is crucial for maintaining the consistency of the shutter doors produced, reducing waste, and minimizing the need for manual intervention.

The operation of the roller shutter door machine is not only efficient but also user-friendly. Operators can easily set up the machine, input production parameters, and monitor the entire process through the user interface provided by the PLC. This reduces the learning curve for new operators and enhances the overall productivity of the manufacturing process.

Additionally, the Shutter Door Roll Forming Machine is designed to be durable and low-maintenance. The high-quality materials and components used in its construction ensure that the machine can withstand the rigors of continuous operation without frequent breakdowns. This long-lasting performance is essential for businesses looking to maximize their return on investment.

For those in the market for a shutter bottom roll forming machine, our product represents the pinnacle of design and functionality. The combination of speed, precision, and control makes this machine an indispensable tool for the mass production of shutter doors. Whether you are starting a new manufacturing line or upgrading your existing equipment, the Shutter Door Roll Forming Machine is designed to meet and exceed the demands of modern production environments.

In conclusion, the Shutter Door Roll Forming Machine is a superior solution for the production of roller shutters. Its combination of 18 roller stations, a forming speed of up to 15m/min, material thickness handling from 0.8 to 1.2mm, and advanced PLC control system make it a highly sought-after machine in the industry. By investing in this rolling shutter machine, manufacturers can look forward to enhanced productivity, impeccable product quality, and a competitive edge in the market.

Features:

-

Product Name: Shutter Door Roll Forming Machine

-

Forming Speed: 0-15m/min

-

Thickness: 0.8-1.2mm

-

Dimension: 6.5m*0.95m*1.2m

-

Roller Stations: 18 Stations

-

Cutting Type: Hydraulic Cutting

-

Commonly referred to as a slat machine

-

Also known as a rolling shutter machine

-

Specializes in making shutter door roll forming

Technical Parameters:

|

Parameter

|

Description

|

|

Product Name

|

Shutter Door Roll Forming Machine

|

|

Dimension

|

6.5m*0.95m*1.2m

|

|

Voltage

|

380V/50Hz/3Phase

|

|

Control System

|

PLC

|

|

Power

|

7.5KW

|

|

Roller Stations

|

18 Stations

|

|

Thickness

|

0.8-1.2mm

|

|

Roller Material

|

45# Steel

|

|

Warranty

|

1 Year

|

|

Weight

|

3T

|

Applications:

The FMS Shutter Door Roll Forming Machine, with its model number designated as "shutter door" and originating from China, is a robust solution for producing high-quality shutter slats for various applications. This machine, which has received CE certification, represents a significant advancement in the roll forming industry and is specifically designed to cater to the needs of businesses requiring efficient and reliable shutter production capabilities.

With a minimum order quantity of just one set and a competitive price of 10000, the FMS Shutter Door Roll Forming Machine is both accessible and affordable to a wide range of customers, from small enterprises to large manufacturing plants. The machine is carefully packaged, arriving naked with protective plastic film to ensure its condition upon delivery, which is guaranteed within 45 days. Payment terms are flexible, accepting both T/T and L/C, and with a supply ability of 20 sets per month, FMS can meet the demand of various scales of operations.

The machine operates at a voltage of 380V/50Hz/3Phase and has a considerable weight of 3T, which underscores its sturdiness and durability. With a power rating of 7.5KW, it is capable of handling extensive workloads without compromising on efficiency or quality. The rollers, made of 45# steel, are engineered to withstand the rigors of continuous operation, thus ensuring a long service life and consistent performance.

The FMS Shutter Door Roll Forming Machine is ideal for a multitude of scenarios, such as the construction of commercial, industrial, or residential buildings where rolling shutters are required for security, energy efficiency, and aesthetic purposes. It is also perfectly suited for companies specializing in the production of various shutter types, as the machine's versatility allows for the production of different sizes and profiles of shutter slats.

As a shutter slat roll forming machine, it is commonly used in shops, garages, warehouses, and other establishments that require robust protection solutions. The rolling shutter machine is also essential in areas prone to adverse weather conditions, as it helps in creating slats that provide protection against storms and hurricanes. Overall, the FMS Shutter Door Roll Forming Machine is a crucial asset for businesses looking to manufacture high-quality shutters efficiently and cost-effectively.

Customization:

Brand Name:

FMS

Model Number:

shutter door

Place of Origin:

China

Certification:

CE

Minimum Order Quantity:

1 set

Price:

$10000

Packaging Details:

Naked with Plastic Film.

Delivery Time:

45 days

Payment Terms:

T/T, L/C

Supply Ability:

20 Set /Month

Cutting Type:

Hydraulic Cutting

Power:

7.5KW

Voltage:

380V/50Hz/3Phase

Dimension:

6.5m*0.95m*1.2m

Roller Stations:

18 Stations

Our FMS shutter door model is a top-performing

roll up door forming machine

, precision-engineered in China. With a robust CE certification, our

rolling shutter machine

comes with a guaranteed quality and a minimum order quantity of just one set. Priced competitively at $10000, this

slat machine

boasts hydraulic cutting and operates on a power of 7.5KW. The voltage requirement is a standard 380V/50Hz/3Phase, making it suitable for many industrial settings. The machine has a solid build with dimensions of 6.5m*0.95m*1.2m and is equipped with 18 roller stations for efficient production. Packaged with care in Naked with Plastic Film, it will be delivered to you within 45 days. We accept payment through T/T and L/C, and our supply capability stands at an impressive 20 sets per month.

Support and Services:

The Shutter Door Roll Forming Machine is equipped with comprehensive technical support and services to ensure smooth operation and long-term reliability. Our support includes detailed product manuals, troubleshooting guides, and access to a team of experienced technicians who can provide expert advice and assistance. We offer regular maintenance tips to keep your machine performing at its best, as well as updates on the latest advancements in technology to enhance your machine's capabilities. Our services also include remote diagnostic support to quickly address any issues that may arise, minimizing downtime and maintaining productivity. Please note that on-site support services can be arranged if required, subject to additional terms and conditions.

Packing and Shipping:

The Shutter Door Roll Forming Machine is securely packaged in a robust wooden case designed to prevent any damage during transit. The wooden case is crafted to fit the machine snugly, with internal padding to absorb any shocks or impacts that might occur. The machine components are also wrapped in protective materials to guard against scratches and corrosion.

Prior to shipping, the wooden case is thoroughly inspected to ensure it is sealed and intact. The package is then marked with the necessary shipping labels and handling instructions to facilitate safe transportation. Our shipping team coordinates with reputable logistics providers to arrange for prompt and efficient delivery to your destination, with tracking options available to monitor the progress of your shipment.

Upon arrival, the recipient is advised to inspect the package for any signs of damage before accepting delivery. In the unlikely event of shipping damage, please report it immediately to the carrier and contact our customer service team for assistance. We take every precaution to ensure that the Shutter Door Roll Forming Machine reaches you in perfect working condition, ready for immediate use in your operations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!