Product Description:

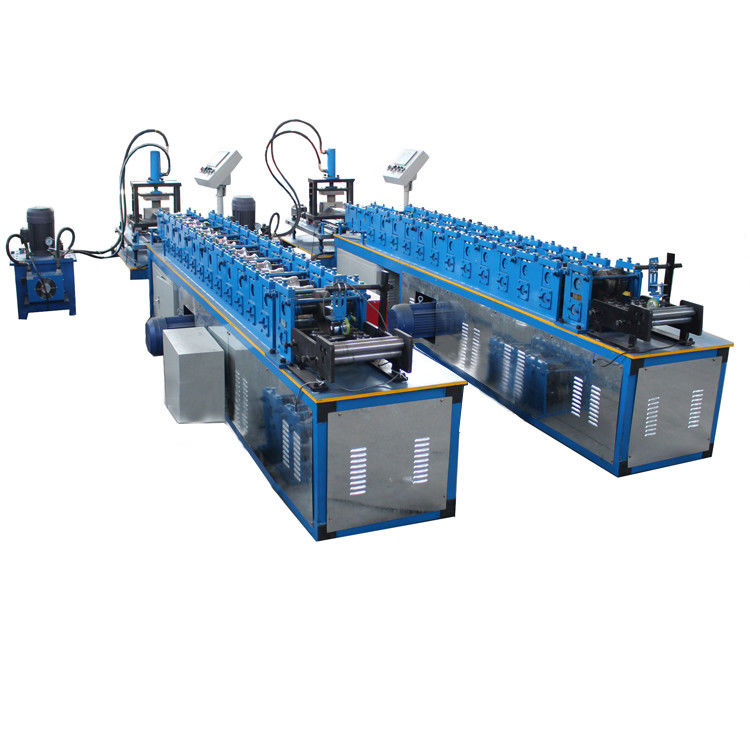

The Shutter Door Roll Forming Machine is a highly specialized piece of equipment designed to produce shutter doors that are widely used in commercial and industrial buildings for security purposes. This machine is capable of turning materials such as Galvanized Steel Coil and Galvalume Steel Coil into fully functional shutter doors through a continuous bending operation, which is carried out by a series of stations where the rolls are the main forming tools.

Our Shutter Door Roll Forming Machine is equipped with a state-of-the-art Control System based on Programmable Logic Controller (PLC) technology. This advanced system ensures seamless automation of the production process, providing high precision and efficiency. The PLC control system allows for easy setting of parameters and monitoring of the roll forming process, ensuring consistent quality and reducing the need for manual intervention.

The rollers, which are the cornerstone of the machine, are constructed from high-quality 45# Steel. This material is renowned for its strength, durability, and resistance to wear, making it an ideal choice for the continuous production of shutter doors. The robust construction of the roller material ensures that the Shutter Door Roll Forming Machine can withstand the rigors of an industrial environment and maintain high levels of productivity over extended periods.

One of the key features of this machine is its Hydraulic Cutting system. This cutting-type guarantees clean, precise, and burr-free cuts, ensuring that each shutter door is finished to the highest standards. The hydraulic cutting mechanism is designed to operate smoothly and reliably, providing quick and accurate cuts without slowing down the production line.

The Shutter Door Roll Forming Machine comes with an extensive warranty of 1 Year. This warranty covers all the essential parts and labor, providing our clients with peace of mind and assurance of our machine's reliability and performance. Our commitment to quality and customer satisfaction is reflected in the comprehensive after-sales support and service that accompanies our warranty.

As a versatile piece of equipment, this machine caters to a variety of shutter door profiles by embodying both a shutter bottom roll forming machine and a shutter slat roll forming machine. The integration of these functionalities allows for the production of complete shutter door systems, including the slats or panels and the bottom sections, which often require additional reinforcement and may feature elements such as end locks or weather seals.

The roller shutter door machine stands out in the market for its precision engineering, robust construction, and high output efficiency. It is designed to handle high volumes of production without compromising on quality, making it an ideal investment for manufacturers looking to scale up their production capabilities in the field of shutter door manufacturing.

In conclusion, the Shutter Door Roll Forming Machine is an exemplary piece of equipment for any manufacturer who requires a reliable, efficient, and versatile solution for the production of roller shutter doors. With its robust construction, advanced PLC control system, precise hydraulic cutting, and the use of high-quality materials such as 45# Steel for the rollers, this machine is set to be a game-changer in the industry. Its comprehensive 1-year warranty and the integration of both shutter bottom and slat forming capabilities make it a valuable asset that can produce a wide range of shutter door products to meet the diverse needs of the market.

Features:

-

Product Name: Shutter Door Roll Forming Machine

-

Weight: 3T

-

Roller Stations: 18 Stations

-

Dimension: 6.5m*0.95m*1.2m

-

Power: 7.5KW

-

Thickness: 0.8-1.2mm

-

Also known as: roll up door forming machine

Technical Parameters:

|

Attribute

|

Details

|

|

Product Name

|

Shutter Door Roll Forming Machine

|

|

Cutting Type

|

Hydraulic Cutting

|

|

Roller Material

|

45# Steel

|

|

Voltage

|

380V/50Hz/3Phase

|

|

Power

|

7.5KW

|

|

Weight

|

3T

|

|

Control System

|

PLC

|

|

Forming Speed

|

0-15m/min

|

|

Warranty

|

1 Year

|

|

Dimension

|

6.5m*0.95m*1.2m

|

Applications:

The FMS brand, renowned for its durable and efficient machinery, presents the Model Number: shutter door roll forming machine, a robust piece of equipment engineered to fabricate high-quality shutter doors. Originating from China, this machine holds the CE certification, ensuring it meets the stringent European standards for quality and safety. It is designed to handle a material thickness ranging from 0.8-1.2mm, making it versatile for various production requirements.

With a minimum order quantity of just one set and a competitive price of $10,000, the FMS shutter door roll forming machine is an accessible solution for businesses of all sizes. Packaging details promise the machine will be delivered naked with plastic film to protect it during transport. The delivery time is set at a reasonable 45 days, providing ample time for manufacturing and shipping without excessive wait times for the customer.

Payment for the FMS shutter door roll forming machine is flexible, with options such as T/T and L/C available, catering to the customer's convenience. Furthermore, FMS demonstrates a significant supply ability, capable of producing up to 20 sets per month, ensuring that demand can be met promptly.

The machine boasts a hydraulic cutting system which is renowned for its precision and reliability. The power of the machine is a robust 7.5KW, enabling it to handle continuous and demanding production cycles. It is compatible with high-quality materials such as Galvanized Steel Coil and Galvalume Steel Coil, which are essential for producing long-lasting and durable shutter doors.

The FMS shutter door roll forming machine is not only a trusted machine for producing standard shutter doors but is also an excellent shutter bottom roll forming machine, offering versatility for producing the bottom profile of rolling shutters. It can also be referred to as a slat machine due to its capability to form the individual slats that make up the shutter doors. The versatility of this machine makes it ideal for a wide range of applications and scenarios, from commercial building projects to residential upgrades.

Customers can invest in this machine with confidence, knowing that it comes with a 1-year warranty, providing peace of mind and assurance of the machine's reliability and the manufacturer's commitment to quality. Whether you need to produce shutter doors for new constructions, replacements, or upgrades, the FMS shutter door roll forming machine, with its precision, efficiency, and reliability, is the optimal choice for your production needs.

Customization:

Brand Name:

FMS

Model Number:

Shutter Door

Place of Origin:

China

Certification:

CE

Minimum Order Quantity:

1 set

Price:

$10,000

Packaging Details:

Naked with Plastic Film.

Delivery Time:

45 days

Payment Terms:

T/T, L/C

Supply Ability:

20 Set / Month

Roller Stations:

18 Stations

Roller Material:

45# Steel

Power:

7.5KW

Dimension:

6.5m*0.95m*1.2m

Forming Speed:

0-15m/min

This FMS shutter door roll forming machine, also known as a slat machine or roll up door forming machine, is expertly crafted in China and certified with CE standards. With a robust construction featuring 18 roller stations made from high-grade 45# steel, it delivers a seamless performance with a forming speed of 0-15m/min. The machine, requiring a minimum order quantity of just one set, is priced at $10,000 and comes with a promise of durability and efficiency. It is packaged with care, ensuring it reaches you in perfect condition, wrapped in plastic film. The estimated delivery time is about 45 days, and the payment can be made through flexible options such as T/T or L/C. With the capacity to supply up to 20 sets per month, FMS ensures that your roll up door forming machine needs are met promptly and professionally. The dimensions of this powerhouse are 6.5m in length, 0.95m in width, and 1.2m in height, drawing a power of 7.5KW to provide unmatched productivity for your manufacturing processes.

Support and Services:

The Shutter Door Roll Forming Machine comes with comprehensive technical support and services to ensure that you can operate your machine efficiently and effectively. Our product support includes an extensive user manual with detailed instructions for installation, operation, and maintenance. We offer troubleshooting guidance for common issues, as well as tips for optimizing machine performance.

In the event of technical difficulties, our dedicated support team is available to provide assistance with diagnosing and resolving machine-related problems. We provide remote support services, which include software diagnostics and updates, to ensure your machine continues to function smoothly.

We also offer a range of preventive maintenance services to keep your Shutter Door Roll Forming Machine in top condition. Regular check-ups and maintenance can help prevent downtime and extend the lifespan of your machine. Replacement parts and repair services are available to address wear and tear or any unexpected damages that may occur during operation.

Training services are available for your personnel to ensure they are fully equipped to operate and maintain the Shutter Door Roll Forming Machine. Our training covers all aspects of machine use, from basic operations to advanced troubleshooting techniques.

For more complex issues or specialized support needs, we can provide on-site assistance from one of our skilled technicians. Our goal is to ensure that your machine maintains optimal performance and that any disruptions to your production are minimized.

Packing and Shipping:

The Shutter Door Roll Forming Machine is securely packaged in a robust wooden case designed to protect the equipment during transit. The case is constructed to withstand long-distance shipping and handling, ensuring that the machine arrives at its destination in pristine condition.

Before shipping, all components of the Shutter Door Roll Forming Machine are carefully inspected to ensure they meet our quality standards. The main forming unit, control system, hydraulic station, and any additional accessories are wrapped in protective material to prevent scratches or damage. The wooden case is then sealed and reinforced to prevent any movement of the contents during transportation.

Upon dispatch, the Shutter Door Roll Forming Machine is loaded onto a suitable freight vehicle using a forklift. It is secured in place to prevent any shifting that could occur while the vehicle is in motion. We work with reliable shipping companies that specialize in the transport of heavy machinery to provide a seamless delivery experience to our customers.

We provide all necessary shipping documents, including a packing list, commercial invoice, bill of lading, and any other required certifications to facilitate a smooth customs clearance process. Our team remains in communication with the customer throughout the shipping process to provide updates and assist with any logistical queries that may arise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!