Product Description:

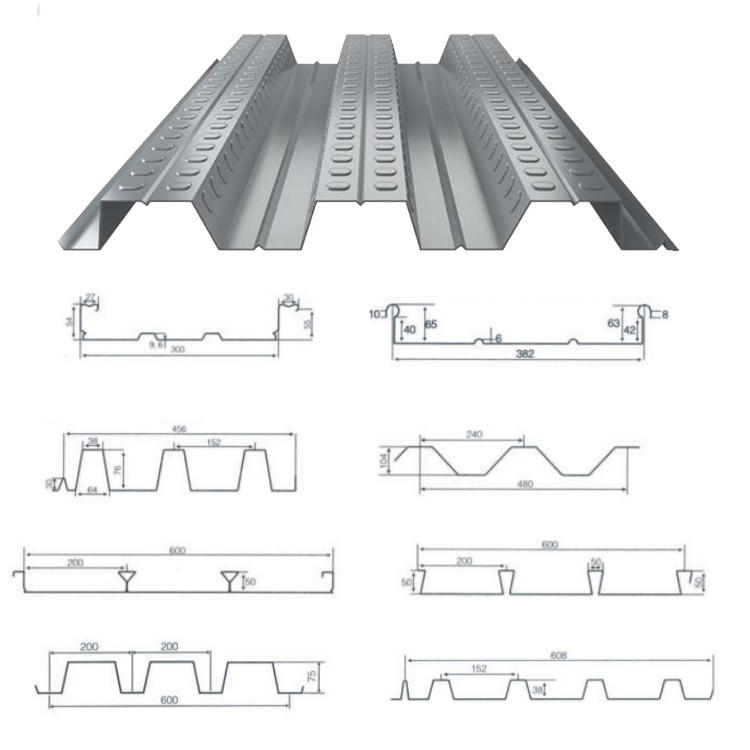

The Floor Deck Roll Forming Machine is a versatile cold roll forming machinery, perfect for manufacturing floor deck roof sheet panels with a thickness of 0.3-0.8mm. This machine is constructed with 45# steel as its shaft material and is capable of forming at a speed of 12-15m/min with 13-18 stations. It is the best floor deck panel roll forming machine for industrial use, providing superior quality and reliable performance.

Technical Parameters:

| Parameter |

Value |

| Thickness |

0.3-0.8mm |

| Control System |

PLC |

| Roller Diameter |

70mm |

| Voltage |

380V/50HZ/3Phase |

| Power |

7.5KW |

| Cutting Mode |

Hydraulic Cutting |

| Cutting Tolerance |

±2mm |

| Roller Material |

45# Steel |

| Weight |

4.5T |

| Shaft Diameter |

50mm |

Applications:

The Galvanized Floor Decking Roll Forming Machine is a highly efficient cold roll forming machinery designed for creating best floor deck panel roll forming machine. It is a versatile machine that can be used to produce different types of panels for various applications. It has a thickness range of 0.3 to 0.8mm and is powered by 7.5KW. The roller stations range from 13 to 18 and it has a hydraulic cutting mode. It is also equipped with a PLC control system for easy operation. Its features make it an ideal choice for producing floor deck panels for many industrial and commercial applications.

Support and Services:

Our Floor Deck Roll Forming Machine is supported by a comprehensive technical support and service program. Our technical support team consists of highly skilled technicians and engineers with extensive knowledge and experience in the industry. They are able to provide assistance with product installation, troubleshooting, maintenance and repair, as well as provide technical advice and assistance on product design.

We offer a variety of service packages designed to meet the needs of our customers. These include on-site maintenance, remote technical support, and a comprehensive warranty program. Our warranty covers all components and labor and is backed by a team of experienced professionals who are committed to providing the highest level of customer service.

We also offer a range of training and education programs designed to ensure that our customers are able to get the most out of their Floor Deck Roll Forming Machine. These courses are tailored to suit each customer's individual needs and can be delivered remotely or on-site. We also provide a range of online resources, including instructional videos, manuals, and troubleshooting guides.

Packing and Shipping:

Packaging and Shipping of Floor Deck Roll Forming Machine

The floor deck roll forming machine is usually packaged in two ways:

- Export standard wooden cases: We use wood cases to pack all parts of the floor deck roll forming machine. This is to ensure that the equipment is safe during the shipping process.

- Container: If the customer needs to ship the floor deck roll forming machine in a container, we will pack the machine in a container according to the customer's requirements, and the customer can directly pick up the floor deck roll forming machine from the port.

FAQ:

Q: What is a Floor Deck Roll Forming Machine?

A: A Floor Deck Roll Forming Machine is a type of machine that is used to make metal floor decks and panels for use in construction and other industrial applications. It is typically used to roll form sheets of metal into the desired shape and dimensions.

2. What are the benefits of using a Floor Deck Roll Forming Machine?

Q: What are the benefits of using a Floor Deck Roll Forming Machine?

A: Floor Deck Roll Forming Machines offer many benefits, such as improved accuracy, increased productivity, and cost savings. They can also reduce labor costs and reduce material waste.

3. What materials can be used with a Floor Deck Roll Forming Machine?

Q: What materials can be used with a Floor Deck Roll Forming Machine?

A: Floor Deck Roll Forming Machines can be used with a variety of materials, including aluminum, steel, and other metals. It is also possible to use plastic and other non-metallic materials.

4. What type of maintenance is required for a Floor Deck Roll Forming Machine?

Q: What type of maintenance is required for a Floor Deck Roll Forming Machine?

A: Regular maintenance is important for any type of machine, including Floor Deck Roll Forming Machines. It is important to regularly inspect and lubricate moving parts, as well as check for any signs of wear or damage.

5. How long does it take to set up a Floor Deck Roll Forming Machine?

Q: How long does it take to set up a Floor Deck Roll Forming Machine?

A: The amount of time it takes to set up a Floor Deck Roll Forming Machine depends on the size and complexity of the machine. Generally speaking, it can take anywhere from a few hours to a few days to set up the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!