Product Description:

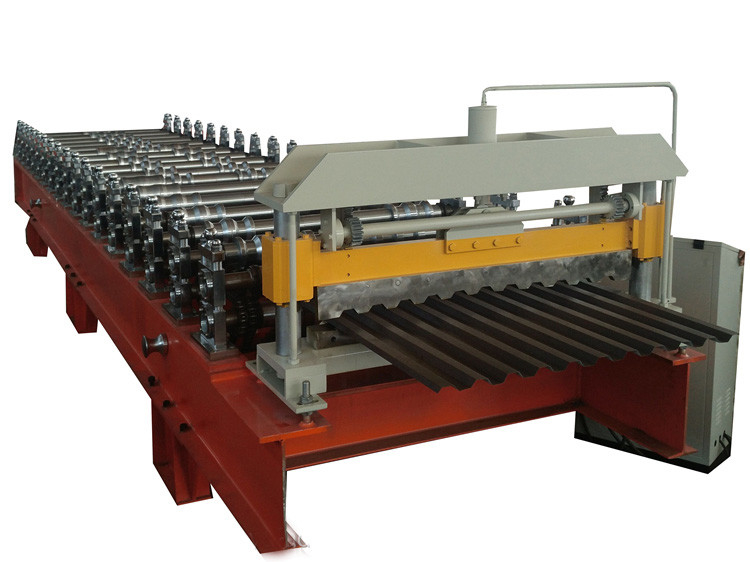

The Wall Panel Roll Forming Machine is a high-end drywall stud roll forming machine that can produce double layer roll forming machines and corrugated roof sheet roll forming machines. It is equipped with high-precision transmission system, featuring a chain transmission, and a hydraulic cutting type that ensures a smooth cutting process. It runs at a speed of 15-20m/min and can be adjusted to fit widths of 100-1000mm. The Wall Panel Roll Forming Machine is powered by a 380V/50Hz/3Phase voltage. This reliable and efficient machine is an ideal choice for any production line.

Features:

- Product Name: Wall Panel Roll Forming Machine

- shaft diameter: 50mm

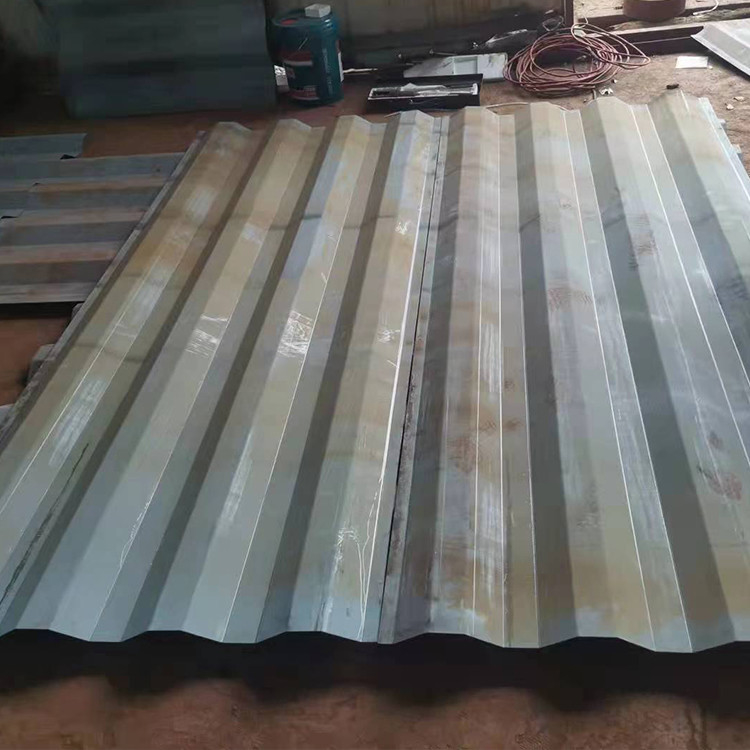

- material: Galvanized Steel

- voltage: 380V/50Hz/3Phase

- roller diameter: 70mm

- cutting type: Hydraulic Cutting

- Corrugated Sheet Roll Forming Machine

- IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine

- Drywall Stud Roll Forming Machine

Technical Parameters:

| Attributes |

Technical Parameters |

| Thickness |

0.3-0.8mm |

| Transmission |

Chain |

| Shaft Material |

45# Steel |

| Cutting Type |

Hydraulic Cutting |

| Roller Material |

45# Steel |

| Width |

100-1000mm |

| Roller Diameter |

70mm |

| Shaft Diameter |

50mm |

| Motor Power |

5.5kw |

| Control System |

PLC |

Applications:

FMS Drywall Stud Roll Forming Machine, Corrugated Sheet Roll Forming Machine, IBR Roof/Trapezoidal/Wall Panel Roll Forming Machine is a reliable and cost-effective solution for producing high-quality roofing, wall panels, and other building materials. It has a brand name of FMS, model number of FMS-roofing tile, place of origin of China, speed of 15-20m/min, shaft diameter of 50mm, control system of PLC, weight of 2.5T, and width of 100-1000mm. This machine is widely used in the construction industry, offering a fast and efficient way of production. It is perfect for producing wall panels, roof tiles, and other building materials. With its robust construction and advanced control system, it can ensure a reliable and consistent result. It is also highly efficient, reducing the production time and cost. This machine is the perfect choice for any construction project that requires high-quality wall panels, roof tiles, and other building materials.

Customization:

Customize Your Wall Panel Roll Forming Machine with FMS

FMS offers custom Wall Panel Roll Forming Machine with the following attributes:

- Brand Name: FMS

- Model Number: FMS-roofing tile

- Place of Origin: China

- roller diameter: 70mm

- roller surface: Chrome Plated

- roller material: 45# Steel

- thickness: 0.3-0.8mm

- voltage: 380V/50Hz/3Phase

Our Wall Panel Roll Forming Machine is perfect for corrugated roof sheet, IBR Roof/Trapezoidal/Wall Panel, Drywall Stud Roll Forming Machine.

Support and Services:

Technical Support & Service for Wall Panel Roll Forming Machine

We provide top-notch technical support and service for our wall panel roll forming machines. Our machines are designed to be durable and reliable, but in the event of a technical issue, we are here to help.

Our team of professional service technicians is highly trained and experienced in all aspects of wall panel roll forming machines. They can quickly identify the root cause of any technical issue and then recommend the most effective solution. We also provide spare parts and timely maintenance services for our machines.

We also offer remote support services, so our technicians can quickly diagnose and troubleshoot any technical issue remotely. We also provide online video tutorials and user manuals to help you better understand and operate our machines.

At Wall Panel Roll Forming Machine, we are committed to providing fast and efficient technical support and service to keep our customers satisfied and their machines running smoothly.

Packing and Shipping:

Packaging and Shipping for Wall Panel Roll Forming Machine:

We will use industrial-grade packaging material to ensure safe transportation of the Wall Panel Roll Forming Machine. We will use bubble wrap, foam, cardboard boxes and wooden crates, depending on the size and shape of the Machine.

We use reliable shipping companies like UPS, FedEx and DHL that provide door-to-door delivery. We also offer air or sea freight services to meet customer requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!