Product Description:

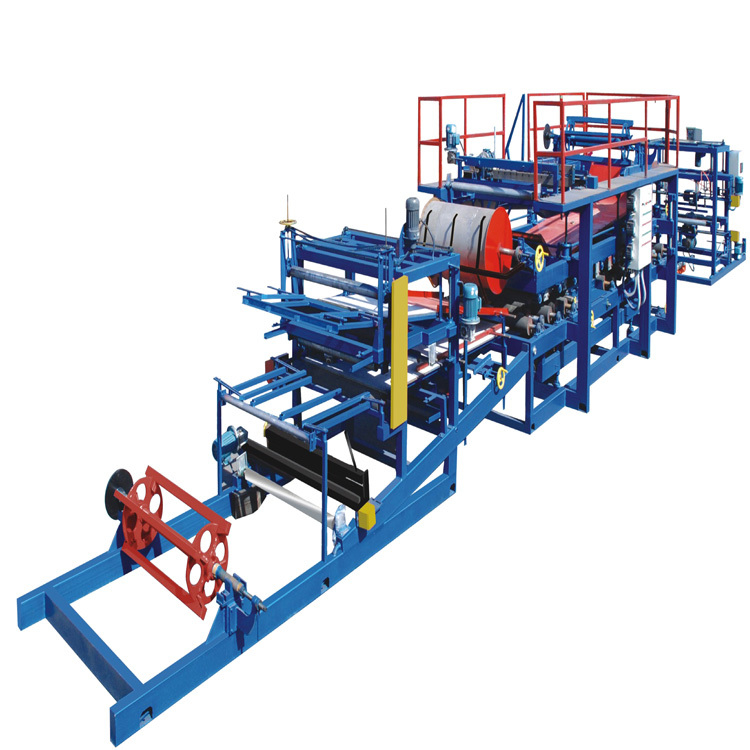

The Sandwich Panel Roll Forming Machine is an ideal solution for producing sandwich roof panel and wall panel. It features voltage of 380V/50HZ/3Phase, dimension of 45m*2.5m*2.4m, forming speed of 3-6m/min, 1 year warranty and roller surface treatment of polishing and chrome plating. This machine is suitable for rock wool sandwich panel production, with high efficiency and reliable performance.

This machine is composed of manual decoiler, roll forming system, cutting system, hydraulic system, PLC control system. The material of the rollers is GCr15 with heat treatment and CNC lathes, with high accuracy and long service life. The cutting blades are made of Cr12Mov with quenching treatment, which is durable and can be used for a long time.

This Sandwich Panel Roll Forming Machine is a perfect choice for producing sandwich roof panel and wall panel. It has high efficiency, reliable performance and long service life, making it the best choice for making rock wool sandwich panel production.

Features:

- Product Name: Sandwich Panel Roll Forming Machine

- Cutting System: Flying Tracking Cutting

- Main Motor Power: Total 32KW

- Roller Surface Treatment: Polishing And Chrome Plating

- Material Thickness: 0.3-0.8mm

- Forming Speed: 3-6m/min

- Special Feature: Sandwich panel production line, EPS sandwich panel line, EPS sandwich panel line machinery

Technical Parameters:

| Parameter |

Value |

| Material Thickness |

0.3-0.8mm |

| Dimension |

45m*2.5m*2.4m |

| Voltage |

380V/50HZ/3Phase |

| Total Weight |

16T |

| Cutting Length Error |

±2mm |

| Control System |

PLC |

| Warranty |

1 Year |

| Roller Surface Treatment |

Polishing And Chrome Plating |

| Material Width |

1000mm |

| Cutting System |

Flying Tracking Cutting |

Applications:

FMS-sandwich is a brand-name rock wool sandwich panel production machine, EPS sandwich panel line, sandwich roof panel and wall panel production line produced by FMS. It has a total motor power of 32KW, and the material thickness ranges from 0.3 to 0.8mm. The material width is 1000mm. The roller surface treatment is polishing and chrome plating. The control system is PLC. This machine is ideal for making rock wool sandwich panel, EPS sandwich panel, sandwich roof panel and wall panel.

The FMS-sandwich is a highly reliable, high-quality production line for the production of rock wool sandwich panels, EPS sandwich panels, sandwich roof panels and wall panels. It has a total motor power of 32KW and a material thickness ranging from 0.3 to 0.8mm. The material width is 1000mm. The roller surface treatment is polishing and chrome plating. The control system is PLC. This machine is ideal for making rock wool sandwich panel, EPS sandwich panel, sandwich roof panel and wall panel.

The FMS-sandwich is a high-precision machine that can produce rock wool sandwich panels, EPS sandwich panels, sandwich roof panels and wall panels with high precision and high quality. It has a total motor power of 32KW and a material thickness ranging from 0.3 to 0.8mm. The material width is 1000mm. The roller surface treatment is polishing and chrome plating. The control system is PLC. This machine is ideal for making rock wool sandwich panel, EPS sandwich panel, sandwich roof panel and wall panel.

The FMS-sandwich is a highly efficient machine that is ideal for the production of rock wool sandwich panels, EPS sandwich panels, sandwich roof panels and wall panels. It has a total motor power of 32KW and a material thickness ranging from 0.3 to 0.8mm. The material width is 1000mm. The roller surface treatment is polishing and chrome plating. The control system is PLC. This machine is ideal for making rock wool sandwich panel, EPS sandwich panel, sandwich roof panel and wall panel.

Customization:

FMS offers custom-made services for Sandwich Panel Roll Forming Machine. Our brand name is FMS, and our model number is FMS-sandwich. The machine is made in China and has a dimension of 45m*2.5m*2.4m. The forming speed is 3-6m/min, and the cutting system is Flying Tracking Cutting. The material width is 1000mm and the cutting length error is ±2mm. This sandwich panel making machine is a perfect solution for sandwich panel production line.

Support and Services:

Technical Support and Service for Sandwich Panel Roll Forming Machine

- 24/7 online technical support, including phone, email and instant messaging support.

- On-site installation and commissioning services.

- Comprehensive training for machine operators.

- Regular maintenance services.

- Regular inspection to ensure machine performance and longevity.

- Access to spare parts and accessories.

- Full replacement or repair guarantee.

Packing and Shipping:

Sandwitch Panel Roll Forming Machine will be packaged carefully with standard wooden box and plastic film for moisture-proof. The size of the wooden box depends on the size of the product.The packaging will be secured with steel straps.

The shipping can be done by sea, air or truck. The shipping cost will vary based on the size, weight, destination and other factors.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!